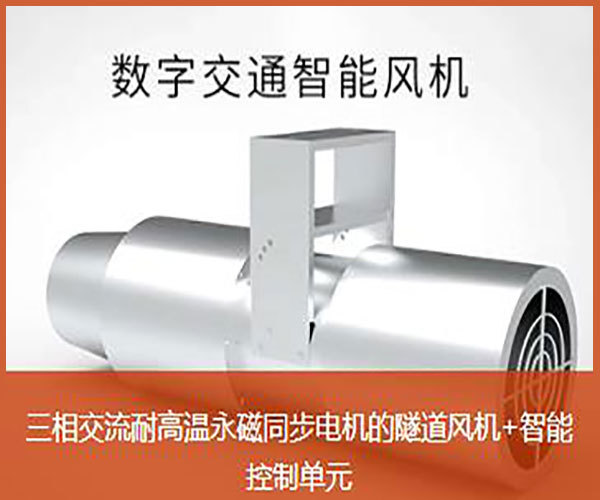

Analysis of Vibration Causes and Malfunctions of Reversible Jet Fans in Pipe Corridors!

The reversible jet fan in the pipe gallery is an important boiler auxiliary equipment for tunnel construction. When the reversible jet fan in the pipe gallery presents difficulties or safety production accidents, it will cause the diesel generator set to reduce the load rate or stop operating, resulting in a harm to the power generation capacity. During the operation of reversible jet fans in pipe galleries, vibration is a common and harmful phenomenon.

Therefore, when vibration problems arise, especially within the warning period of the problem, it is of great practical significance to make appropriate diagnoses at high speed. Simple diagnosis is based on the vibration or other information content of the machine equipment, without the need for expensive instruments and equipment. Generally, a general vibration meter and a self-made listening needle are used to identify the cause of the vibration problem of a reversible jet fan in a general pipe gallery through methods such as listening, seeing, touching, and smelling.

1. Vibration caused by unbalanced rotor quality

In the vibration of the roller bearings of the reversible jet fan in the pipe gallery on site, the majority of the vibration is attributed to the imbalance of rotor quality. The key reasons for the unbalanced quality of the rotor of the reversible jet fan in the pipe gallery are: uneven wear or erosion of the centrifugal impeller (mainly the leaves); Uneven accumulation of dust or residue and metal oxides (such as rust) on the surface of leaves; The hollow leaves or other parts of the aircraft wing are covered with dust inside the cavity; Part of the main shaft bearing is bent due to high temperature; The centrifugal impeller was not balanced after maintenance; Insufficient compressive strength of the centrifugal impeller causes cracking or partial deformation of the centrifugal impeller; The parts on the centrifugal impeller are loose or the mating parts are not tightened.

2. The vibration caused by rubbing in the middle of the sound part

Such as collision between the inlet and outlet of the collector and the inlet of the centrifugal impeller, collision between the centrifugal impeller and the casing, and collision between the main shaft bearing and the sealing installation. Its vibration characteristics: unstable vibration; Vibration is self-excited, and the ratio of vibration to rotational speed is irrelevant; When friction is severe, it can cause reverse vortex motion.

3. Abnormal vibration occurs in the assembly line

If there are abnormalities in the production and processing of the motor shaft or shaft ring table, the motor shaft will bend, the roller bearing assembly will be skewed, and the inner hole of the roller bearing of the centrifugal fan for tunnel construction will not overlap with the pivot axis after assembly on the assembly line, causing the axial force effect of the roller bearing to alternate every revolution. The fixed circular nut of the roller bearing will loosen, causing some vibration. Its vibration characteristics are: the vibration value is greater than the shaft diameter; The vibration frequency is the same as the rotational frequency.

4. Vibration caused by surface damage of dynamic roller bearings

Roller bearings may be damaged due to poor manufacturing quality, abnormal smoothness, dirt entering, and gaps with the roller bearing housing that do not meet standards. After being worn, rusted, peeled off, and cracked, high-frequency impact vibrations caused by collisions between steel balls will be sent to the seat bearing. By placing an instantaneous velocity sensor on the seat bearing, high-frequency impact vibration data signals can be detected. The vibration reliability of the reversible jet fan in the pipe gallery is very poor and is not related to the load. The amplitude of the vibration may be large in the horizontal, vertical, and axial directions. The detailed diagnosis of the vibration depends on frequency band analysis. The application of frequency band analysis can accurately identify the precise location and level of damage to the roller bearing, which does not need to be elaborated here.

The vibration problem of reversible jet fans in pipe galleries is very complex, but by manipulating the causes and fundamental characteristics of various vibrations, coupled with frequent sedimentation, it is possible to quickly and accurately identify the source of the vibration problem of reversible jet fans in pipe galleries, and take effective measures to develop the safety and stability of reversible jet fans in pipe galleries. For more information about jet fans, reversible jet fans for pipe galleries, and bidirectional jet fans, please follow our website updates.

Related News