How to clean and repair the reversible jet fan in the pipe gallery?

How to clean and repair the reversible jet fan in the pipe gallery? When using a reversible jet fan with a pipe gallery, it can only move forward at full speed. At the same time, in order to ensure sufficient power and stable voltage, the power supply line is a dedicated line and temporary lines should not be used for a long time. During the operation of the reversible jet fan in the pipe gallery, it was found that the fan had abnormal sound, severe heating, charged casing, tripped switch, and could not be started. The inspection should be stopped immediately. To ensure that the reversible jet fan of the pipe gallery is not allowed to be maintained during operation and use. After maintenance, debugging and inspection should be carried out for about 5 minutes to confirm that there are no abnormal phenomena before starting operation.

In order to ensure good lubrication of the reversible jet fan in the pipe gallery during operation, the refueling time should not be less than 1000 hours each time. Sealed bearings and motor bearings are strictly prohibited from operating without oil. When using a reversible jet fan in a pipe gallery, it is important to maintain and clean the fan properly. Regularly clean and inspect the fan to ensure the normal operation of the reversible jet fan in the pipe gallery. When not in use, place it in a dry and clean place to prevent damage from moisture. The reversible jet fan in the pipe gallery should be stored in a dry environment to prevent the motor from getting damp. When stored outdoors, rainproof measures should be taken. During storage and handling, collision with the fan should be prevented to prevent damage to the reversible jet fan in the pipe gallery.

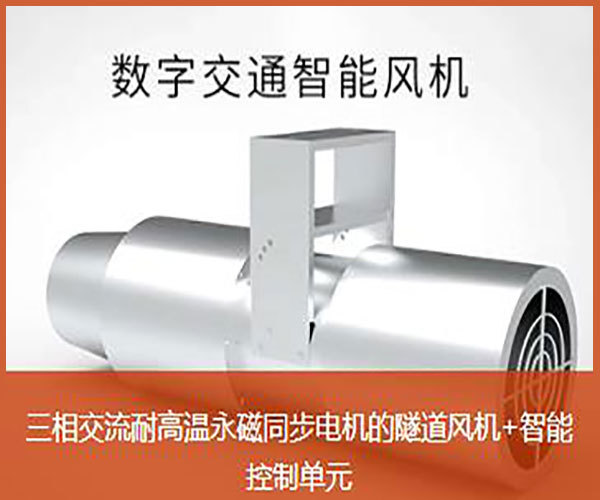

The reversible jet fan in the pipe gallery has the characteristics of high efficiency, obvious energy-saving effect, low noise, and long gas supply distance. It is suitable for high-pressure ventilation in places such as metallurgy, nonferrous metals, gold, chemical industry, ships, ceramics, etc. Ensure that the working environment of the reversible jet fan in the pipe gallery is clean and tidy, with a clean surface and no impurities at the inlet and outlet.

Regularly clean the dust and other impurities on the fan and pipeline.

Regularly inspect the lubrication system of the reversible jet fan in the pipe gallery and clean the oil filter. Regularly check whether the oil has become turbid, mixed with water or other pollutants, and deteriorated. If the situation worsens, please replace the oil and check the normal oil drip nozzle of the reversible jet fan in the pipe gallery every day. For example, remove the dirty dropper and clean the adjusting screw. For more information about jet fans, reversible jet fans for pipe galleries, and bidirectional jet fans, please follow our website updates

Related News