Digital tunnel exhaust gas purification device products

Categories:

Keywords:Ventilation equipment

Telephone:

E-mail:

Digital tunnel exhaust gas purification device products

Details

tunnel ventilation system

The main ventilation mode of highway tunnel is to adopt inclined shaft, vertical shaft and parallel guide tunnel to form a ventilation system of sending and discharging polluted air out of the tunnel and sending fresh air out of the tunnel into the tunnel. The construction of inclined shafts, erection and construction requires requisition of mountainous areas and destruction of mountain vegetation.

The ventilation mode of urban tunnel is similar to the vertical# (inclined shaft) ventilation mode of highway tunnel. The wind tower is constructed with longitudinal ventilation of wind tower, which will reduce the urban green area or relocate residents.

Whether it is a highway tunnel or an urban tunnel, the ventilation method can only discharge the polluted air in the tunnel to the outside of the tunnel, increasing the air pollution outside the tunnel. The use of air purification system will help reduce or cancel the construction of shafts, inclined shafts or wind towers, reduce the concentration of pollutants in the air in the tunnel, improve air quality, and reduce the outward emission of polluted air in the tunnel.

Tunnel Polluted Air Composition

According to the measurement statistics of tunnel polluted air (tunnel discharge outlet), the polluted air in the tunnel comes from automobile exhaust smoke emission, tire friction, brake, diesel engine smoke emission and surface friction of auxiliary equipment in the tunnel. The main pollutants are ultrafine particles and nitrides. Fine particulate matter (Particulate Matter) is mainly PM10 particles and PM2.5 particles. Ultrafine particles are extremely difficult to block, easy to be inhaled into the human body after entering the bronchus, causing diseases including asthma and cardiovascular disease. Nitride NOxMainly NO and NO.2NO is an unstable gas and is easily oxidized to NO.2. The purification of particulate matter and chemical substances in the air in the tunnel will improve the air quality in the tunnel, protect the driving environment of the tunnel, reduce the emission to the outside of the tunnel, and realize the energy-saving operation of the tunnel.

Principle of electrostatic dust removal

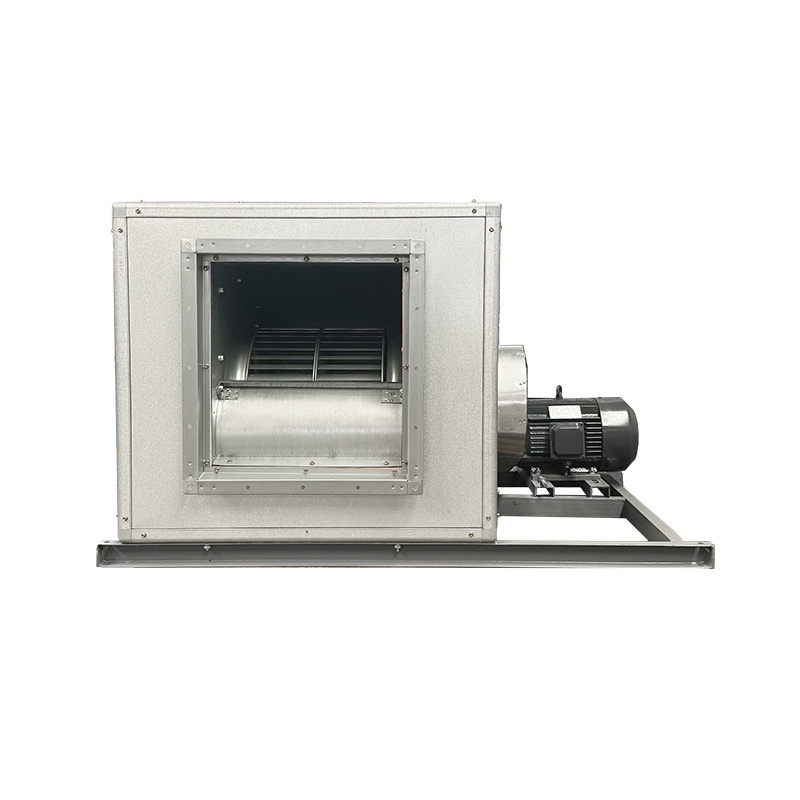

The main sources of smoke particles in the tunnel are automobile exhaust dust, tire friction, brake braking, diesel engine smoke emission and surface friction of ancillary facilities in the tunnel. Among them, diesel smoke particles and tire brakes, clutch friction and pavement particles are the main sources of pollution. With the increase of the tunnel slope, especially the maximum longitudinal slope of the project reaches 3.5%, the smoke and dust gas becomes the main pollution source in the tunnel. Electrostatic dust removal equipment (ESP) is a dust removal equipment that uses high-voltage electric field to separate the polluted particles in the gas from the air, which can effectively reduce the smoke and dust gas in the tunnel.

The use of electrostatic precipitator ESP(Electrostatic Precipitator) in road tunnel ventilation equipment has the following two main purposes: to improve the vision and air quality of the driver inside the tunnel; to reduce the pollution of the tunnel to the external air environment.

Product Technical Description of Digital Tunnel Exhaust Gas Purification Device

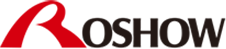

The suspended ceiling purification station is composed of multiple systems, including: dust collector, automatic cleaning equipment, water treatment equipment, power distribution equipment, control equipment and other supporting equipment. It is a complete set of product equipment. Its main technical requirements are as follows. Our company can carry out sub-deepening design according to the project design dust removal technical requirements.

1. Dust removal system

The suspended ceiling dust removal system is a system for removing particulate matter discharged from vehicles in the tunnel and is located at the top of the tunnel. The exhaust gas in the tunnel is adsorbed by the fan in the system, purified by photo-oxygen catalytic disinfection through the primary filter and electrostatic filter, and then discharged into the tunnel.

Electrostatic Precipitation Filter (ESP): A device that uses a high-voltage power supply (DC or AC) generator to form an electric field between the anode and cathode of a charged metal plate, thereby trapping particulate matter in the gas. When the collector plate is covered with dust, it can be washed with special cleaning water spray, and then used again after heating and drying. The electrostatic filter shall have measures to avoid the influence of arc ignition on the purification efficiency.

In addition to the electrostatic dust filter (ESP), the ceiling air purification system also includes the following auxiliary equipment:

(1) Electrostatic dust removal filter (ESP) automatic cleaning system:

(2) High voltage device of electrostatic precipitator filter (ESP);

(3) Axial flow fan and electric air valve;

(4) Air monitoring, control systems and instruments;

(5) Waste water and solid waste treatment system (only applicable to ceiling dust removal system);

(6) Relevant equipment and accessories required to achieve the performance of the technical terms and drawings of the air purification system.

2. Operating conditions

The air purification system of this project is divided into normal working conditions and emergency working conditions:

(1) Normal working condition refers to the normal working condition and blocking working condition of vehicles in the tunnel.

① The air purification system (APS) can operate fully automatically under normal working conditions, and can be operated locally through the local control panel on site when necessary. Local control on site is a priority.

② The operation can be terminated under the following conditions

a. Maintenance period;

B, dust removal system ventilation system large axial fan stop working

C, emergency conditions.

(2) Emergency conditions refer to the following conditions in the tunnel

a. Fire or smoke in any part of the tunnel:

B. Power interruption;

C, ventilation system emergency.

Under emergency conditions, the air purification system (APS) shall be able to automatically shut down and automatically cut off the air purification system (APS) from the tunnel ventilation system.

When the air purification system (APS) is restarted after an emergency condition, the restart procedure shall be approved by the Owner.

3. Monitoring and control system

(1) The air purification system should be able to achieve fully automatic control and achieve the following objectives:

The air purification system can automatically start and stop according to the preset program.

② Determine the efficiency of the electrostatic precipitator filter (ESP), and automatically realize the entire operation process of flushing the electrostatic precipitator filter, (ESP) automatic cleaning, filtering/circulating flushing water, and drying the electrostatic precipitator filter.

③ Local control of air purification system equipment on site.

(2) The air purification system shall complete the following safety controls: ① The air chamber of the ceiling air purification system shall be equipped with an access control lock, which shall interlock and cut off the power supply of the electrostatic dust removal filter. The access control lock key can only be kept by authorized inspectors, and only authorized inspectors can activate the electrostatic precipitator filter power supply under safe conditions.

② The fan dust removal system shall be equipped with an access control lock, which shall be interlocked to cut off the power supply of the electrostatic dust removal filter. The access control lock key can only be kept by authorized inspectors, and only authorized inspectors can activate the electrostatic precipitator filter power supply under safe conditions.

③ automatic fire alarm system linkage control to cut off the electrostatic precipitator filter power supply.

④ Automatic fire alarm system linkage control to close the axial flow fan and electric combined air valve.

(3) The control facility interface shall be provided for the central control and monitoring system, and the air purification system shall provide monitoring status for the central control and monitoring system

① Operating status of all subsystems and main/critical components;

② Timely identify the fault status of major subsystems and major/critical components

③ Real-time monitoring of electrostatic precipitator (ESP);

④ Monitor the air quality, temperature, humidity and pressure drop monitoring values of the electrostatic precipitator filter (ESP) in real time.

4. Air quality control

The gas discharged from the tunnel portal after being treated by the air purification system shall meet the requirements of Class II standard in the GB3095-2012 of Ambient Air Quality Standard, and shall not be lower than the pollutant limit given in the environmental assessment report of the project.

5. Noise control

The noise level source of the electrostatic dust removal system will not release additional noise to the tunnel and the environment. Ensure that the source of the noise level will not transmit the higher noise level in the ventilation system to the tunnel under the design airflow of the electrostatic dust removal system, and discharge the air treated by the air purification system into the air.

6. Waste water discharge control The ceiling purification station is provided with a waste water circulation device to avoid waste water discharge; the waste water discharge concentration of the fan-type dust removal equipment meets the discharge standard.

7. Solid waste discharge control

A detailed solid waste disposal plan shall be prepared and submitted to the Owner for approval.

Online message