RTF CENTRIFUGAL ROOF FAN (ALL ALUMINUM)

Categories:

Impeller diameter:250~1000mm

Range of air volume:1000~50000m³/h

Range of Pressure : 80pa

Operating Temperature :280℃,30min

Drive form : direct /belt drive

Keywords:Ventilation equipment

Telephone:

E-mail:

RTF CENTRIFUGAL ROOF FAN (ALL ALUMINUM)

Details

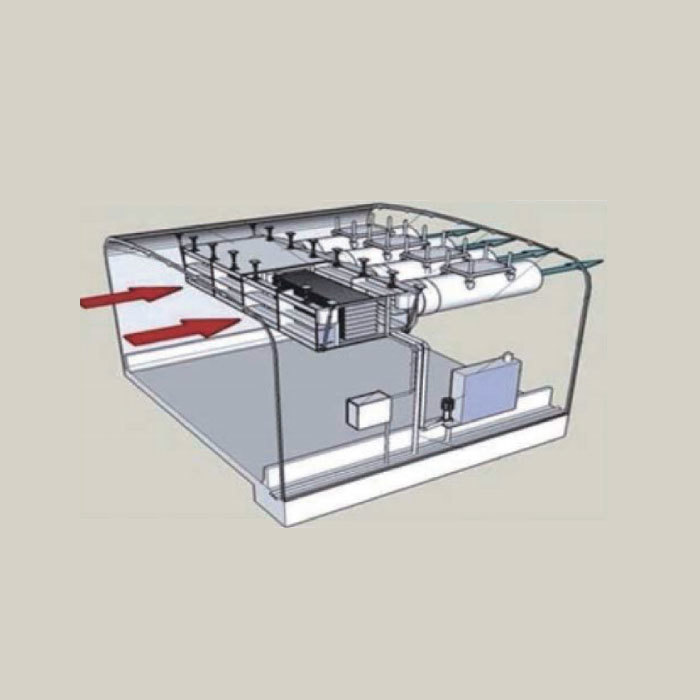

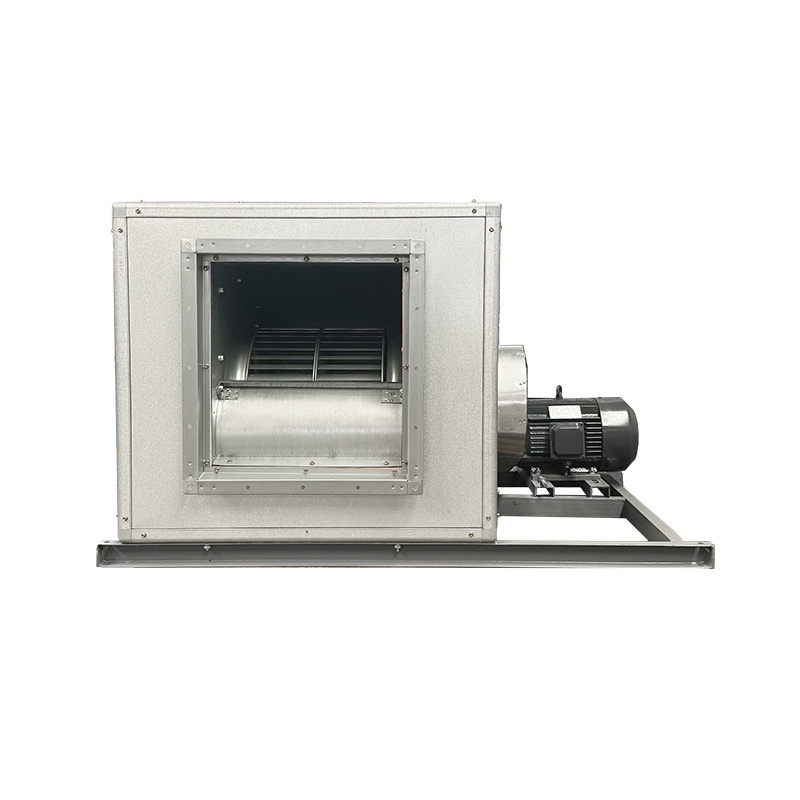

This series of fans are divided into 300, 425, 500, 575, 675, 750, 900 and 1000 according to impeller diameter, with a total of 8 specifications. The air volume ranges from 1275m3 /h to 55215m3 /h and the maximum static pressure reaches 650Pa. The fan is composed of impeller, motor, casing, hood, collector, fixed bracket and other components. Optional: fire damper, check valve, etc. Material: special aluminum alloy.

1. product features

1. Fan impeller: The high and low aluminum alloy impellers with advanced technology and optimized design are introduced. The front disc, rear disc, and blades of the impeller are processed by multiple processes such as stamping, blanking, and molding. The structure is compact and has large air volume and noise. Features such as low and high efficiency.

2. Fan matching motor: with protection grade IP54 and insulation grade F motor, if equipped with insulation grade H, the product can be continuously subdivided in a high temperature environment of 300/45min; In addition, explosion-proof motors, two-speed motors and frequency conversion motors can also be equipped.

3. Shell: The overall structural strength of the fan is designed according to the conditions of 50 m/s extreme outdoor wind speed. The fan is made of aluminum alloy. After stretching, crimping and other processing, under the premise of ensuring sufficient strength of the fan, the appearance of the fan is improved. Beautiful, reduce the weight of the fan, reduce the strength requirements for the roof foundation, and have good wind resistance.

4. The hood is made of high-quality aluminum alloy, stretched and formed as a whole, and is hemmed, with light weight, high strength and low wind resistance.

5, collector: the use of high quality and reasonable design, a molding process, so that the impeller guide and air inlet fully consistent, effective control of air flow organization, in line with the fluid mechanics of the hyperbolic inlet, greatly reduce the inlet noise, improve fan efficiency.

6. Fixed bracket: CNC blanking and molding, multi-station CNC punching machine processing fixed holes, easy installation. 7. Transmission device: This series of fans adopt belt drive and direct connection.

8. Air valve: gravity automatic closing type or electric drive opening and closing type. The frame of gravity automatic closing air valve is made of hot galvanized plate, and the louver is made of aluminum alloy. The blades of the electric drive opening and closing air valve are made of aluminum alloy thermal insulation louvers, which are anti-condensation and anti-airflow backflow. They are especially suitable for use in severe cold areas in the north. Smoke exhaust and ventilation are used for two purposes. Smoke exhaust fire dampers can be selected. Fans and smoke exhaust fire dampers have passed the national fire products.

9. Installation and maintenance: The motor protective cover adopts a buckle and fixed structure, which is convenient to operate and saves time and effort.

10. Smooth operation: The rotational inertia of this fan is small, the balance quality is excellent, and the balance quality reaches the G 2.5 balance quality level of the IS01940 standard. The whole machine has undergone mechanical operation test, vibration test and aerodynamic test to ensure that it meets the requirements of running balance and reliability, effectively prolongs the service life of the fan, reduces noise and reduces vibration.

Note: The rotating speed of the fan in the performance parameter table is: 460r/min, 560r/min, 960r/min, 1450r/min The transmission mode can be directly connected with the motor.

2. naming convention

In order to clearly and completely describe the main information of the fan, the following is a detailed explanation of the naming method of the fan:

Selection of 3. fan

1. This series of fans are only limited to conveying gas without solid particles (not more than 150m/m3)

2. Fan sound pressure level test: measured at 1.5m of fan inlet.

3. The same number of fans can also be made into axial flow roof fans under the conditions of air volume and air pressure.

Previous

Next

Online message